He cooperates with key OEMs and suppliers to help them gain a better insight during production or product development resulting in improved processes and higher quality. AMS Automotive Evolution Summit On-Demandĭave Robinson, Product Manager, Nikon Metrologyĭave specialises in CMM and laser scanning products and has more than 15 years of experience in automotive metrology applications.Use automatic feature-tracking tools to quickly create curve networks.≡ Create smooth and logical NURBS surfaces easily editable in CAD software Apply all typical CAD operations directly to polygonal models and prepare these models for a wide variety of manufacturing applications such as milling, rapid prototyping, reverse engineering, inspection, CFD & FEA, digital review and so on.Reconstruct perfect polygonal features from imperfectly digitized geometry.Transform aligned point clouds into highly accurate polygonal models using PolyWorks' unique tolerance-based adaptive meshing technology.≡ Generate manufacturable class A polygonal models PolyWorks/Modeler TM (for reverse engineering) allows you to: Verify the compliance of final manufactured and assembled products through sample check inspection using automated techniques.Monitor the production cycle by automatically measuring the wear of tools and quickly detecting any abrupt degradation in product quality.Approve your manufacturing process by fully inspecting your first-assembled products.

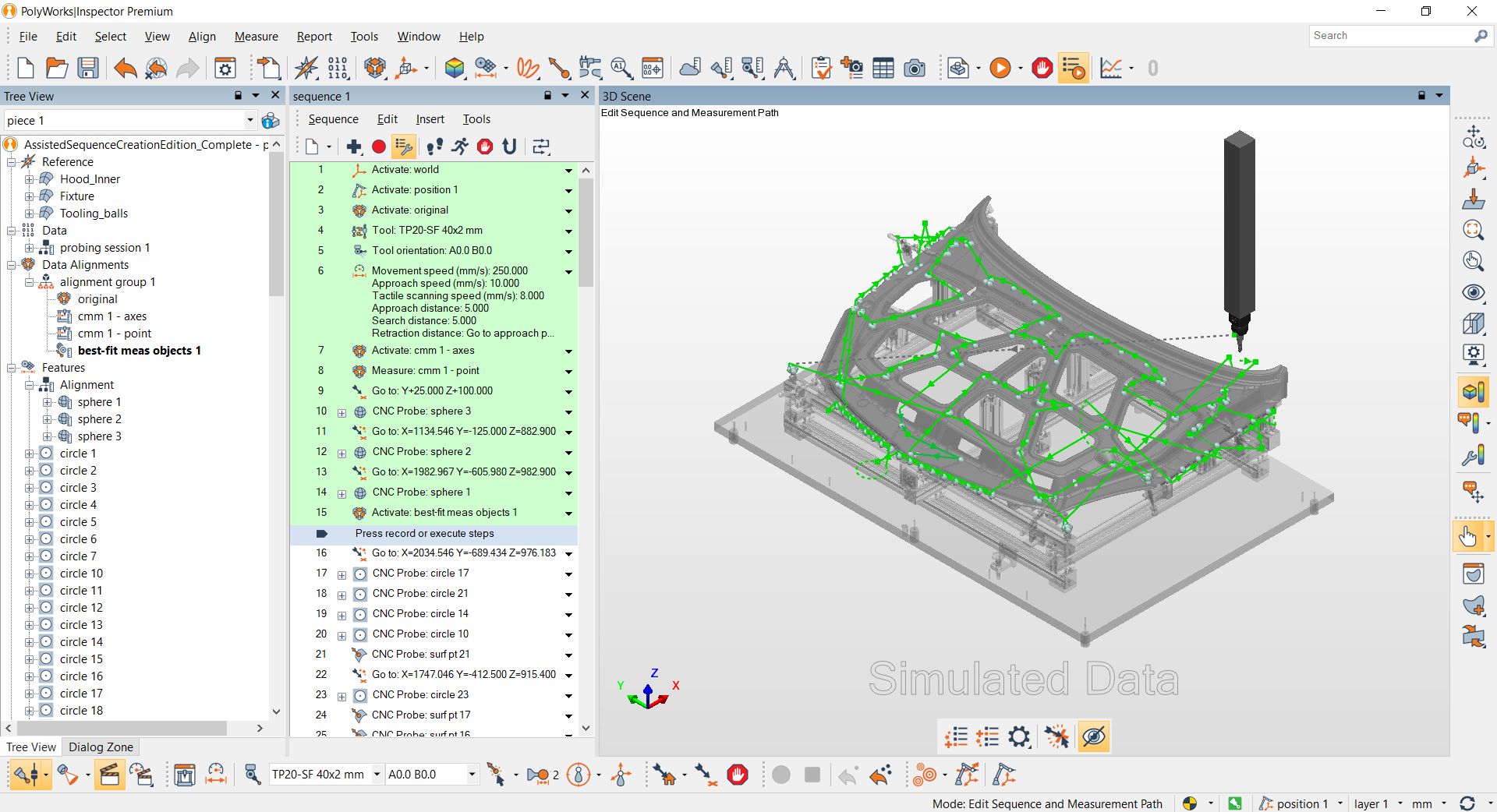

Use high-density point clouds of digitized prototype parts & assemblies to quickly identify deformations and to fix problems in the earlier stage of the manufacturing process.PolyWorks/Inspector TM (for point cloud inspection) allows you to:

0 kommentar(er)

0 kommentar(er)